Insulated expansion ladders are a specialized breed of ladders designed with electrical safety in mind. They serve a dual purpose of providing elevation and offering protection against electrical hazards. These ladders are commonly utilized by electricians, utility workers, and maintenance personnel who frequently engage in tasks involving live electrical circuits or equipment.

The Basics of Insulated Expansion Ladders

Insulated expansion ladders are crafted to deliver both height and insulation. They enable users to reach elevated workspaces while safeguarding them from potential electrical shocks. In electrical tasks where contact with high voltage is a risk, these ladders prove indispensable, ensuring operator safety and compliance with stringent electrical standards.

Importance in Electrical Work

The primary importance of insulated expansion ladders lies in their ability to enhance safety during electrical tasks. By preventing electricity from traveling through the ladder itself, they significantly reduce the risk of electric shocks. These ladders meet various electrical safety standards, making them essential tools for professionals working around live circuits.

Construction and Design

Material Composition

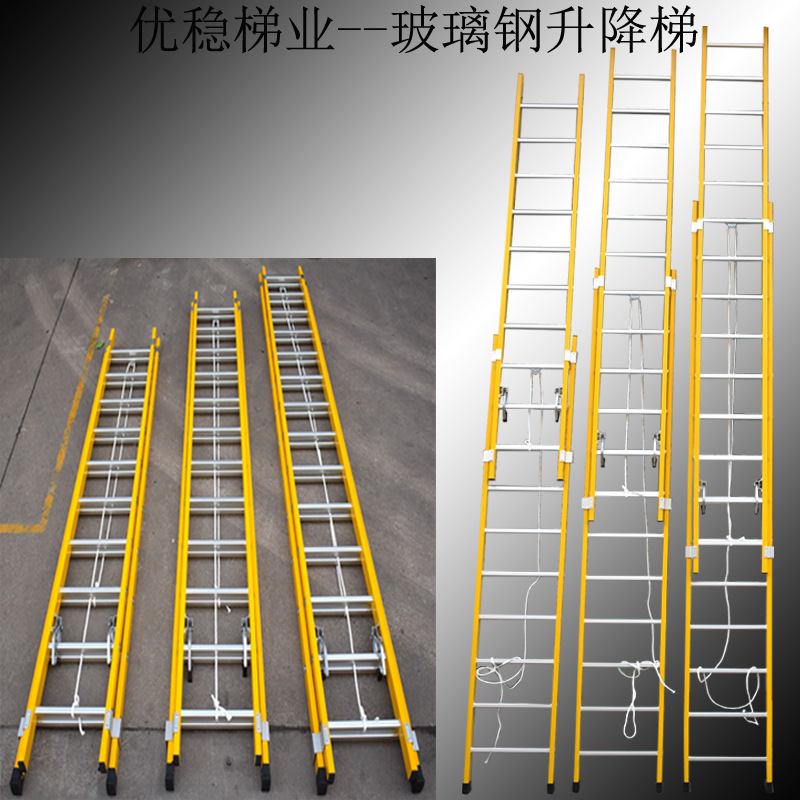

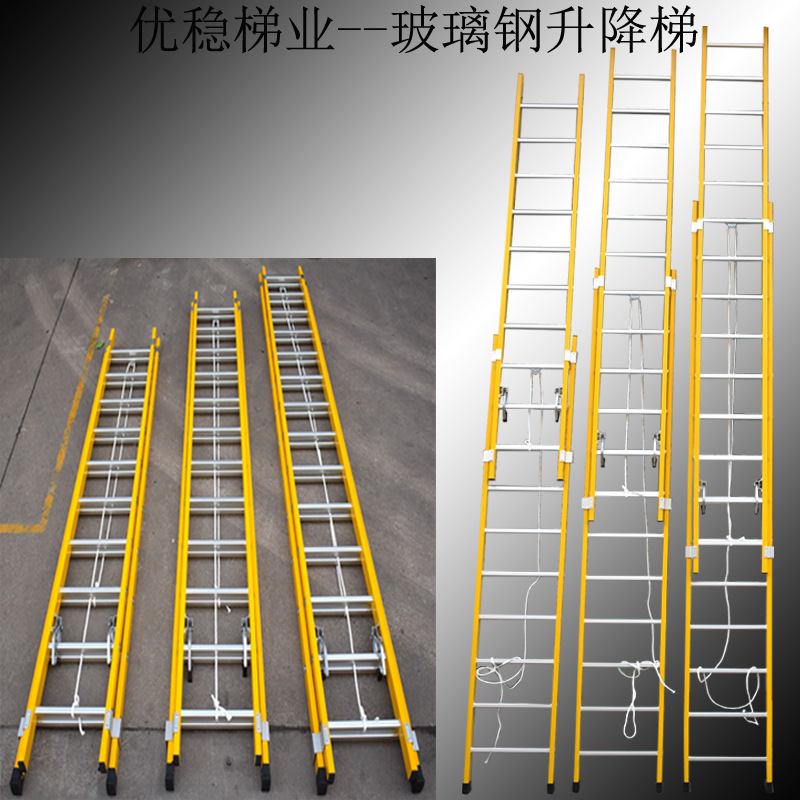

Most insulated expansion ladders are constructed using materials like fiberglass and aluminum. Fiberglass is the preferred material due to its superior insulating properties and durability. On the other hand, aluminum may be used in specific non-conductive coatings to strengthen structural integrity without compromising on insulation.

Structural Features

Key features of these ladders include telescopic sections that allow for easy extension and retraction. This capability supports flexibility and convenience, enabling workers to adjust the ladder length to suit the task at hand. Stability-enhancing design elements such as wide bases and anti-slip feet ensure user safety even when operating at extended heights.

Insulation Mechanism

Electrical Insulation Properties

The unique combination of chosen materials ensures that insulated expansion ladders exhibit excellent resistance to electrical conductivity. Standards and certifications validate these insulation properties, guaranteeing that each ladder conforms to industry requirements for safe operation around electrical systems.

Built-in Safety Features

Additional built-in safety mechanisms bolster the ladder's value. Non-conductive coatings provide an extra layer of protection, while safety locks prevent accidental movement or collapse. Users can confidently handle the ladders without fearing unexpected extensions or retractions that could lead to accidents.

Operational Mechanics

Extension and Retraction Process

Operating an insulated expansion ladder involves several steps. First, inspect the ladder for any damage or wear before use. To extend, unlock the safety latches and pull out the necessary sections until the desired height is achieved. Securely lock all sections into place before climbing. Retraction requires releasing the locks and carefully sliding the sections back to their compact form, making sure no parts snag or pinch along the way.

Load Capacity and Stability

These ladders come with specified maximum load ratings, which should never be exceeded to maintain stability. Robust construction and stable design features ensure that the ladder can support the user's weight alongside necessary tools, providing a secure platform during operation.

Practical Applications

Use in Various Electrical Tasks

In practical scenarios, insulated expansion ladders find applications in a variety of electrical tasks. From residential wiring installations to commercial electrical system maintenance, these ladders offer unparalleled safety and reliability. Case studies highlight instances where these ladders have prevented serious injuries by protecting workers from electrical surges.

Maintenance and Inspection

Maintaining the ladder's functionality and safety profile requires regular inspections for signs of wear and tear. Look for cracks, broken rungs, or damaged coatings. Proper storage practices, such as keeping the ladder in dry, clean environments away from corrosive substances, prolong its life span and effectiveness.

Advantages Over Traditional Ladders

Enhanced Safety

When compared to traditional non-insulated ladders, insulated expansion ladders present significant safety advantages. Regular ladders pose severe risks if inadvertently contacted with live wires, whereas insulated options mitigate this hazard entirely. Specific accident reports underscore the enhanced protection provided by these advanced ladders.

Versatility and Ease of Use

Beyond safety benefits, these ladders also offer remarkable versatility. Easily adjustable telescopic sections accommodate different working conditions, and lightweight models facilitate transportation. User-friendly designs improve operational efficiency, allowing electricians to adapt quickly to varying project demands.

Future Trends and Innovations

Technological Advancements

Emerging technologies promise further advancements in ladder design. The development of new materials with improved insulation and strength characteristics continues to evolve. Additionally, integrating smart technology, such as sensors to detect proximity to live wires, represents the next frontier in ladder innovation.

Market Trends

The demand for insulated expansion ladders is steadily increasing, driven by heightened awareness of workplace safety. Industry developments reflect this trend with more manufacturers investing in research and development. Future predictions suggest a continuous evolution toward more sophisticated, safer ladder solutions tailored to the needs of modern professional environments.